Achieving Sustainability: Continuous Improvement for Waste Reduction

Linea

|

PDF

In today’s world, sustainability has become more than just a buzzword; it’s a fundamental aspect of doing business responsibly. One of the key components of sustainability is waste reduction. Businesses that actively seek ways to minimise waste not only contribute positively to the environment but also stand to benefit financially and enhance their reputation. Continuous improvement for waste reduction is a crucial strategy for any business looking to thrive in an environmentally conscious marketplace.

The world is facing several sustainability challenges, such as climate change, pollution, and resource depletion. These challenges are complex and interconnected, and they will require a concerted effort from everyone to address them.

Continuous improvement is a never-ending process of finding ways to do things better, more efficiently, and more effectively. When applied to sustainability, continuous improvement can help organisations reduce their environmental impact, improve their resource efficiency, and create a more sustainable future.

Here are some statistics that demonstrate the importance of continuous improvement in sustainability practices:

The world produces 2.01 billion tons of waste every year. That’s enough to fill 800,000 Olympic-sized swimming pools.

Only 9% of the world’s plastic waste is recycled. The rest ends up in landfills, incinerators, or the environment.

The average person produces about 4.4 pounds of trash per day. That’s enough to fill a small bathtub in a year.

If we continue to produce and consume waste at the current rate, we will produce 3.4 billion tons of waste by 2050. Reducing waste is one of the most important things we can do to protect the environment. It can help to reduce pollution, conserve resources, and mitigate climate change. There are many ways to reduce waste. We can recycle, compost, reduce our consumption, and choose sustainable products.

Even small changes can make a big difference. If everyone reduces their waste by just 10%, we can save millions of tons of waste every year.

In addition to this, there are many different types of resource wastage that occur in organisations, such as the poor performance of factory resources, the poor quality of operational processes due to unsustainable practices, and so on.

We are committed to implementing continuous improvement strategies in our processes. We believe that by constantly striving to improve our processes and practices, we can make a positive impact on the environment.

Waste generation in business encompasses a broad spectrum, including physical waste (e.g., excess materials, packaging), energy waste (e.g., inefficient processes), and even human potential waste (e.g., underutilised talent and ideas). All forms of waste have a common negative impact on a business’s bottom line, its environmental footprint, and its overall sustainability efforts.

Cost Implications:

Waste represents a significant, often hidden cost for businesses. Materials wasted in production, excess energy consumption, and inefficient processes can eat into profits. By actively reducing waste, businesses can cut costs and increase profitability.

Environmental Impact:

Waste disposal of particularly hazardous waste, can have detrimental effects on the environment. Reducing waste not only lessens pollution but also conserves natural resources and minimises the carbon footprint.

Reputation and Stakeholder Expectations:

In an era when consumers are increasingly eco-conscious, a business’s environmental practices can significantly affect its reputation. Companies committed to waste reduction and sustainability are more likely to attract environmentally aware customers and investors.

Continuous improvement for waste reduction involves an ongoing effort to identify, assess, and mitigate waste in all aspects of a business’s operations. Here’s how businesses can embark on this journey:

Conduct Waste Audits:

The first step in reducing waste is to understand where it’s coming from. Conduct regular waste audits to identify sources and quantify the types and amounts of waste generated.

Set Clear Goals:

Establish specific, measurable, achievable, relevant, and time-bound (SMART) goals for waste reduction. These goals should align with your overall sustainability strategy.

Educate and Engage Employees:

Encourage all employees to take an active role in waste reduction. Training programs and regular communication can help instil a culture of waste consciousness.

Lean Principles:

Implement lean manufacturing or lean management principles to minimise waste in processes, eliminate bottlenecks, and enhance efficiency.

Sustainable Procurement:

Choose suppliers and partners who share your commitment to waste reduction and sustainability. Opt for products and materials with minimal packaging and consider the environmental impact of your supply chain.

Technology and Innovation:

Embrace technology to monitor and optimise resource usage. Invest in energy-efficient equipment, use data analytics to identify waste hotspots, and explore innovations in waste reduction.

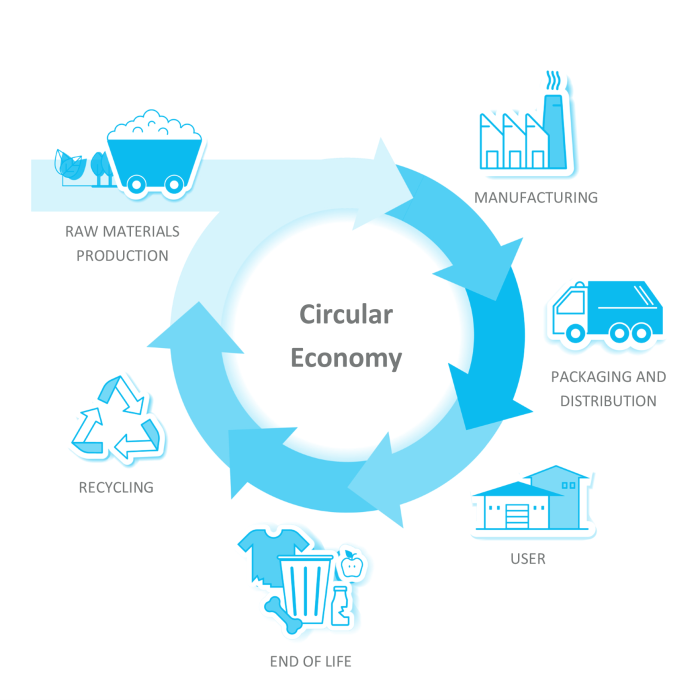

Recycling and Circular Economy:

Explore recycling and repurposing opportunities for waste materials within your organisation. Consider adopting a circular economy model where products and materials are designed for reuse or recycling.

Continuous Monitoring and Measurement:

Regularly track progress toward waste reduction goals. Use Key Performance Indicators (KPIs) to assess the impact of your efforts.

Employee Feedback and Ideas:

Encourage employees to share their waste reduction ideas and reward innovative solutions. Employee involvement can yield valuable insights and motivate teams to actively participate.

Transparency and Reporting:

Communicate your waste reduction achievements transparently to stakeholders, customers, and investors. Demonstrating your commitment to sustainability can enhance your brand’s reputation.

We envisage a world that stands tall on the pillars of continuous improvement and sustainability. This vision encompasses a cycle of never-ending enhancement, where both individuals and organisations work collaboratively towards building a sustainable future.

Definition of “continuous improvement in sustainability”?

Defining continuous improvement in sustainable development involves understanding the dynamic process wherein businesses or communities enhance their policies, strategies, and actions to promote sustainability over time. It is an ongoing effort, steering towards a future that prioritises environmental, social, and economic wellbeing.

The Interlinking of Sustainability and Continuous Improvement

Delving deeper, we find an intricate connection between sustainability and continuous improvement, two concepts that power our vision.

Sustainable Improvement Meaning

Sustainable improvement refers to the process where improvements are not just a one-time endeavour but a continuous effort, aligned with the principles of sustainability, ensuring long-term benefits.

Continuous Improvement Sustainability Definition

This term is defined as a sustained effort directed towards the systemic improvement of processes, products, or services with the central objective being sustainability.

Developing a continuous improvement sustainability model

Formulating a model, encompassing all essential elements for sustainability, facilitates a streamlined approach towards continuous improvement.

Developing a continuous improvement sustainability model

Formulating a model, encompassing all essential elements for sustainability, facilitates a streamlined approach towards continuous improvement.

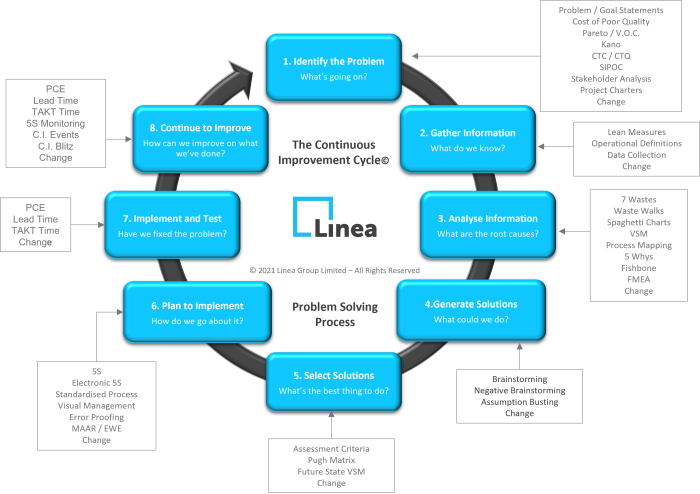

We identify opportunities for Continuous Improvement through the adoption of the Linea Continuous Improvement Cycle (C.I.C). It provides a structured 8 step process for Continuous Improvement, applied at various organisational levels, ensuring a best practice approach that is renowned for supporting clients to deliver quality, efficiency & cost reduction improvements, sustainably.

C.I.C is fundamental to our extensive track record of deploying best practice excellence across public sector industries, by facilitating a process which clearly articulates the steps needing to be taken to understand & deliver system requirements.

Is continuous improvement always possible?

The journey towards the unceasing enhancement of sustainability procedures presents a complex landscape fraught with significant obstacles. Central to these challenges is securing unfaltering endorsement and advocacy from senior management; their long-term commitment forms the backbone of sustained efforts in steering the organisation towards a path of continuous enhancement. The endeavour also brushes up against a fundamental human reluctance to alter established patterns, a resistance that augments when individuals find comfort in the existing state of affairs through repetition, custom and practice.

However, a pertinent question looms – is the aspiration for constant improvement a feasible objective? Here, one confronts the omnipresent focus on immediate gains, a phenomenon prevalent in numerous firms, overshadowing the broader perspective that emphasises long-term benefits derived from a steadfast adherence to sustainable strategies. This scenario delineates a daunting task where convincing stakeholders to invest substantial resources, without the lure of instant results, becomes an uphill battle.

Monitoring continuous improvement: Tools and strategies

It is irrefutable that the employment of precise metrics stands as a pivotal element in the equation. The initiative to foster sustainability rests heavily on the ability to meticulously monitor developments through quantifiable indicators. However, a conspicuous absence of such metrics in several organisations obstructs a clear vision of the progress trajectory, relegating the endeavour to a speculative arena devoid of concrete data.

Moreover, a robust training framework emerges as a critical requisite, furnishing individuals with a deep-seated understanding of the core principles that govern the realm of continuous improvement. It posits an environment where learning is nurtured, and personnel are adeptly equipped with the necessary tools to navigate the complexities that the process entails. Thus, encapsulating a vision that transcends mere economic growth, aiming for an ecologically harmonious future underpinned by informed strategies and operational excellence.

Continuous improvement for waste reduction is not a one-time initiative but a holistic approach to running a sustainable and responsible business. By adopting waste reduction as a core value, organisations can not only reduce costs but also contribute to a healthier planet and attract customers who prioritise eco-friendly practices.

In today’s competitive landscape, where sustainability is a key differentiator, embracing continuous improvement for waste reduction is not just an option—it’s a strategic imperative for long-term success. Businesses that make waste reduction a priority will not only thrive financially but also leave a positive impact on the world for generations to come.

Click below to chat to a team member